Terminating Fiber in the Field

There are three basic approaches to terminating fiber connections in the field: adhesive connection and field polishing, mechanical connectors and no polishing, or fusion splicing using pigtail assemblies. Let’s take a brief look at each.

Field Polish / Adhesive terminations

Adhesive connectors are a very common option. With these terminations, a 1- or 2-part system adhesive is injected into the connector, and the fiber is inserted. An accelerator or “primer” can be used to cure the adhesive more rapidly.

Adhesive terminations are the least expensive option. However, they are very craft sensitive, so labor costs are a consideration. Also, a word of caution: The Telecommunications Industry Association (TIA) has tightened its requirements single-mode return loss (reflectance), at 0.35 dB. Meeting those requirements becomes much more challenging with field polish connections. With enterprise networks moving to higher speeds, return loss is now more of a concern than ever. Minimizing return loss requires improving your polishing procedures, or choosing a factory polished connector such as mechanical terminations.

Factory polish / mechanical connections

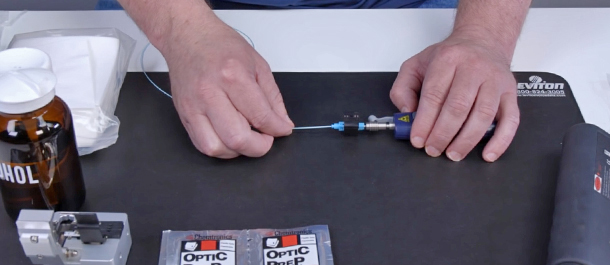

Traditionally, mechanical connectors were considered a temporary “quick-fix” solution. However, the technology in mechanical connectors has advanced over the years, and the advantages have made them higher quality long-term solution. With mechanical connectors, the end-faces are factory-polished and highly controlled, leading to better insertion loss and return loss. However, this termination option will cost more than field polished connectors and will require a precision cleaver.

Leviton FastCAM connectors are pre-polished, field-installable connectors that eliminate the need for hand polishing, bonding, or epoxy in the field. See the video overview below for how to terminate the FastCAM connecter with 900 micron fiber. We’ve also blogged in the past with tips for installing FastCAM.

Fusion splicing

Fusion splicing is another option that uses factory polished connectors and will provide excellent insertion and return loss. However, it is also more expensive than field polishing, and will require a greater capital investment as it requires both a precision cleaver and a fusion splicer. The good news is the cost of fusion splicers has come down in price significantly in recent years.

Leviton offers pigtails and splice modules to protect and organize heat shrink fusion spliced fibers inside an enclosure. The modular design enables faster field splicing and simple management of pigtails within the housing. Splice modules eliminate the need for individual splice trays within a fiber enclosure. The video below shows how to terminate Leviton Opt-X SDX Splice Modules.